When a roller chain is used, shaft positions is often arbitrarily determined. Even so, in principle, observe the illustration shown beneath. That is definitely, if your chain is tensioned horizontally, preserve the top rated tensioned. Steer clear of vertical transmission whenever doable. In an inevitable situation, place the massive sprocket at the bottom irrespective of the path of rotation.

Once the chain layout is undesirable:

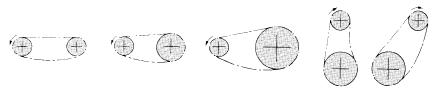

?When the prime is sagging along with the sprocket center distance is quick:

As illustrated beneath, adjust the sprocket center distance shaft to do away with the sag.

?Once the top is sagging as well as sprocket center distance is long:

As illustrated beneath, set up an idler from within to reduce the sag.

?When the chain is vertical or inclined:

Remove the extra sag by a tensioner. In this case, a tensioner that automatically eliminates the sag offers improved outcomes.

When a pulsating load acts in high velocity operation:

The chain’s vibration plus the load effect frequency or chordal action may possibly synchronize to amplify vibration to the chain. Given that vibration influences the chain, get countermeasures to prevent vibration while in the following measures:

?Modify the chain velocity.

?Enhance chain stress.  Even so, note that over-

Even so, note that over-

tensioning can shorten the life on the chain. ?Use an idler or tensioner to divide the span

?Install a guide stopper to avoid vibration.

Note: Chordal action refers for the vertical movement of chain induced when it truly is engaged with sprockets.