Micro motor features

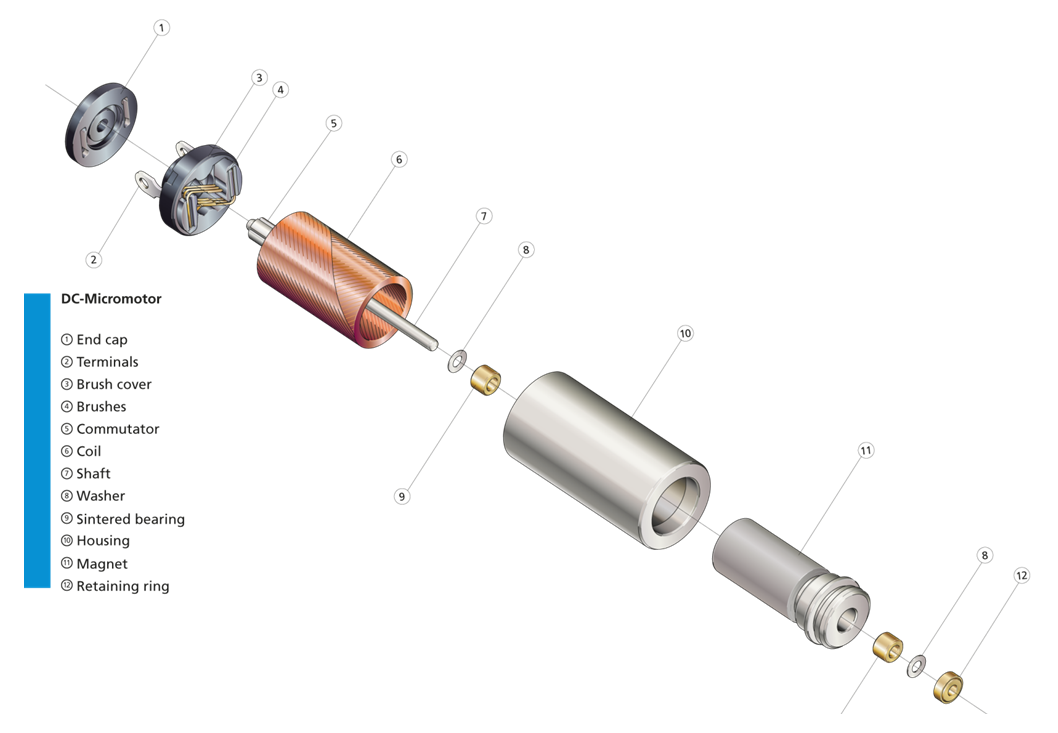

The primary difference between our DC micro agricultural Chain motors and conventional DC motors is in the rotor. The rotor doesn’t have an iron primary but contains a self-helping skew-wound copper winding. This featherweight rotor comes with an extremely low moment of inertia, and it rotates without cogging. The result is the exceptional dynamics of our motors. For low power micro motors, commutation systems using precious metals are the optimum solution because of their low contact level of resistance.

Our  precious steel commutated motors range in proportions from simply 6 mm to 22 mm in diameter.

precious steel commutated motors range in proportions from simply 6 mm to 22 mm in diameter.

We complete the drive system by providing a variety of additional hightech standard components including high res encoders, precision gearheads, and drive electronics. We focus on the modification of their drive systems to fi t the customer’s particular program requirements. Common modifications include vaccuum compatibility, intense temperature compatibility, altered shaft geometry, extra voltage types, customized micro motor potential clients and connectors, plus much more.

Micro motor benefits

Ideal for battery operated devices

No cogging

Extremely low current consumption – low starting voltage

Highly dynamic performance because of a minimal inertia, low inductance winding

Light and compact

Precise speed control

Simple to control due to the linear performance characteristics