Regular Grid Spacer and Half Spacer Style Couplings Horizontal Cover

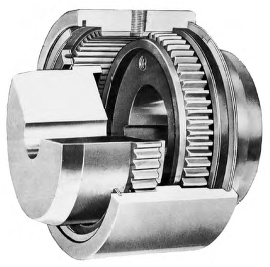

The Grid Spacer coupling is definitely an perfect coupling for applications where there’s a necessity for some vibration dampening in installations that are not close coupled. This implies some level of gap, or BSE exists in between the driver and driven tools shafts.

All Grid Spacer Couplings are provided with Horizontal Split Covers. The split cover design lets for quick entry to your grid spring for ease of upkeep or grid spring replacement. The Horizontal Split Cover is also ideal for applications in which there could be some constraints to the diameter from the coupling.

Capabilities:

Intended for ease of servicing and grid spring substitute

High tensile grid springs make sure superior coupling functionality and longer coupling existence

Split covers make it possible for for easy access to grid springs

Interchangeable with sector conventional grid couplings

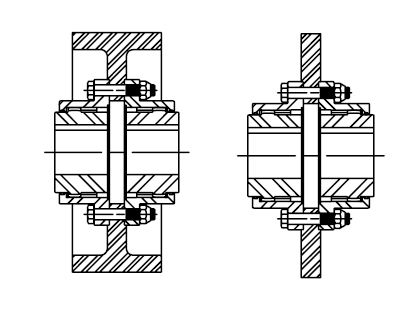

Regular Grid Design Couplings Horizontal and Vertical Cover

The Grid coupling is an suitable coupling for applications the place superb efficiency is preferred and further demands for vibration dampening might exist. The Horizontal Split Cover design is suggested in applications wherever there may be some constraints

on the diameter in the coupling. The vertical design and style is advisable for applications  exactly where increased speed is probably the necessities.

exactly where increased speed is probably the necessities.

Attributes:

Created for ease of servicing and grid spring replacement

Higher tensile grid springs assure superior coupling effectiveness and longer coupling lifestyle

Split covers enable for simple access to grid springs

Interchangeable with sector conventional grid couplings

pump applications and servicing

pump applications and servicing Resistance to centrifugal separation

Resistance to centrifugal separation a flex half within the top rated.

a flex half within the top rated. nut threads.

nut threads. way of dimension 5.five.

way of dimension 5.five. lets for greater shaft diameters

lets for greater shaft diameters for higher strength

for higher strength This coupling is supplied with rigid hubs outboard unless of course otherwise specified. Exposed bolts are conventional. Shrouded bolts are available on request tru sizes 5.five.

This coupling is supplied with rigid hubs outboard unless of course otherwise specified. Exposed bolts are conventional. Shrouded bolts are available on request tru sizes 5.five.