S-Flex Sleeves

Versatile sleeves for S-Flex couplings are available in three components (EPDM, Neoprene, and Hytrel) and in 3 essential patterns: a single piece reliable, one-piece split, or two piece

JE, JN, JES and JNS Varieties

JE and JN Form sleeves function a one-piece reliable design

JES and JNS Variety sleeves feature a one-piece split style

JE and JES Kind sleeves are molded in EPDM materials

JN and JNS Kind sleeves are molded in Neoprene materials

E and N Varieties

E and N Variety sleeves characteristic a two-piece layout with retaining ring

E Style sleeves are made from EPDM material and therefore are offered in sizes 5-16

N Style sleeves are made from Neoprene material and therefore are readily available in sizes 5-14

Two piece sleeves are best for applications in which compact shaft separations inhibit the installation of the 1 piece sleeve

H and HS Varieties

H and HS Sort sleeves are created for higher torque applications, transmitting about 4 times as significantly electrical power as an equivalent EPDM or Neoprene sleeve

Hytrel sleeves are available inside a one-piece sound (H) or two-piece split (HS) building

Hytrel sleeves could be utilized only with S or SC flanges and will not be utilized with J or B flanges

Hytrel sleeves should really not be made use of as  direct replacements for EPDM or Neoprene applications

direct replacements for EPDM or Neoprene applications

H and HS Variety sleeves are available for sizes 6-14 (sizes 13 and 14 can be found in HS only)

Archives

admin

February 22, 2021

Procedure

S-Flex Coupling Variety Course of action

The assortment process for determining the right S-Flex coupling calls for using the charts shown to the following pages. There are actually three elements to be picked, two flanges and a single sleeve.

Facts important in advance of a coupling might be chosen:

HP and RPM of Driver or working torque

Shaft size of Driver and Driven tools and corresponding keyways

Application or tools description

Environmental disorders (i.e. severe temperature, corrosive ailments, area limitations)

Steps In Deciding on An S-Flex Coupling

Step 1: Identify the Nominal Torque in in-lb of one’s application by using the following formula:

Nominal Torque = (HP x 63025)/RPM

Phase two: Applying the Application Service Issue Chart one pick  the services factor which very best corresponds to your application.

the services factor which very best corresponds to your application.

Step 3: Determine the Design and style Torque of the application by multiplying the Nominal Torque calculated in Step one through the Application Services Component established in Stage 2.

Style Torque = Nominal Torque x Application Services Aspect

Stage four: Applying the Sleeve Overall performance Data Chart 2 decide on the sleeve materials which best corresponds to your application.

Step 5: Employing the S-Flex Nominal Rated Torque Chart three find the appropriate sleeve material column for the sleeve selected in Step four.

Phase six: Scan down this column for the to start with entry the place the Torque Worth in the column is greater than or equal to your Design and style Torque calculated in Phase three.

Refer towards the maximum RPM worth in the coupling size to guarantee that the application needs are met. If the maximum RPM worth is much less than the application necessity, S-Flex couplings are certainly not recommended to the application.

Note:

If Nominal Torque is less than 1/4 with the coupling’s nominalrated torque, misalignment capacities are diminished by 1/2. As soon as torque value is located, refer to your corresponding coupling size within the initially column of the S-Flex Nominal Rated Torque Information Chart three .

Stage seven: Review the application driver/driven shaft sizes to the highest bore dimension readily available on the coupling picked. If coupling max bore just isn’t substantial enough to the shaft diameter, decide on the subsequent biggest coupling which will accommodate the driver/driven shaft diameters.

Stage 8: Making use of the Item Choice tables, find the appropriate Keyway and Bore size expected and find the variety.

admin

February 22, 2021

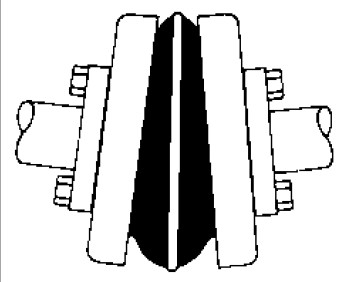

We provide versatile sleeve for S-Flex coupling in three models: one-piece sound, one-piece split, and two-piece with retaining ring

The one-piece split style offers answers for applications with distinctive needs the place smaller shaft separations inhibit the installation of a one-piece solid sleeve

Pre-molded teeth along the diameter of your sleeve engage with teeth in the coupling flanges

No clamps or screws are desired to connect the flanges together with the flexible sleeve which securely lock together below torque for smooth transmission of power

Torque is transmitted via shear loading with the sleeve

All three sleeve components are extremely elastic which permits the S-Flex coupling to safeguard linked equipment from damaging shock loading, vibration, and shaft misalignment

JE, JN, JES, JNS Sleeve Styles

These sleeves attribute a one-piece layout molded in EPDM & Neoprene rubber. In the case of JES & JNS Styles, the one-piece style is split to provide for ease of set up and removal.

E, N Sleeve Styles

These sleeves characteristic a two-piece style and design with retaining ring. The E Type is molded in EPDM rubber and the N Type is molded in Neoprene. The two-piece style is ideal for applications exactly where there is difficulty in separating the shafts of your driver and driven.

H, HS Sleeve Styles

These sleeves function both a one-piece reliable (H) and two-piece split

(HS) style and design and are molded of Hytrel. The sleeves in Hytrel material are designed to transmit power for high torque applications. Because of your design and style and the properties with the Hytrel molded sleeve, the H and HS sleeves should not be used as direct replacements for EPDM or Neoprene sleeves, and can only be used with S, TF, or SC flanges.

Sleeve Elements

EPDM ?§C Unless otherwise specified, S-Flex couplings are supplied with EPDM versatile sleeves. EPDM has good resistance to commonly used chemicals and is generally not affected by dirt or moisture. Color is black.

NEOPRENE ?§C Neoprene delivers very good performance characteristics for most applications and offers a very good resistance to chemical and oil conditions. Color is black with a green dot.

HYTREL ?§C Hytrel is a polyester elastomer designed for  high torque and high temperature applications and offers excellent resistance to chemical and oil conditions. Color is orange.

high torque and high temperature applications and offers excellent resistance to chemical and oil conditions. Color is orange.

admin

February 22, 2021

Elastomer In Shear Style Couplings

The straightforward style and design with the S-Flex coupling guarantees ease of assembly and trusted performance. No particular equipment are essential for set up or removal. S-Flex couplings may be utilized in a wide selection of applications.

Functions

Uncomplicated to put in

Maintenance No cost

No Lubrication

Dampens Vibration and Controls Shock

Torsionally Soft

Double Engagement

Traits and Functionality Details

The S-Flex coupling layout is comprised of 3 parts: two flanges with internal teeth engage an elastomeric flexible sleeve with external teeth

Torque is transmited through the flanges mounted on both the driver and driven shafts via the sleeve

Misalignment and torsional shock loads are absorbed by shear deflection while in the sleeve

The shear characteristic on the S-Flex coupling is quite effectively suited to soak up influence loads

The S-Flex coupling offers combinations of flanges and sleeves which could be assembled to suit your distinct application

Thirteen sizes can be found with torque capabilities that vary from 60 in-lbs to 72,480 in-lbs

The S-Flex flanges are made available in 5 designs that are made from zinc or cast iron

Sleeves are available in EPDM rubber, Neoprene to tackle a wide selection of application requirements

Safety from misalignment, shock, and vibration:

PARALLEL:

The S-Flex coupling accepts up to .062 in of parallel misalignment with no wear. The flexible coupling sleeve minimizes the radial loads imposed on products bearings, a problem normally connected with parallel misalignment.

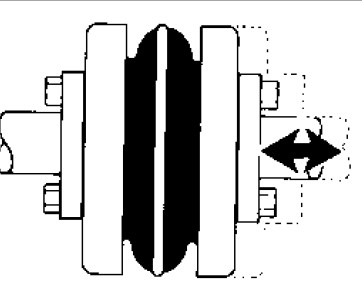

AXIAL:

The S-Flex  couplings is usually utilized in applications which require a constrained volume of shaft end-float without transferring thrust loads to products bearings. Axial movement of around 1/8 inch accepted.

couplings is usually utilized in applications which require a constrained volume of shaft end-float without transferring thrust loads to products bearings. Axial movement of around 1/8 inch accepted.

ANGULAR:

The flexing action with the elastomeric sleeve as well as locking attribute of the mating teeth makes it possible for the S-Flex coupling to efficiently handle angular misalignment up to 1??.

TORSIONAL:

S-Flex couplings proficiently dampen torsional shock and vibration to safeguard connected gear. The EPDM and Neoprene sleeves have torsional wind-up flexibility of 15?? at their rated torque. Hytrel delivers 7??wind-up.

admin

February 20, 2021

H Sort Couplings

The H Sort coupling consists of two hubs, two inside  sleeves, a single cushion set and a single collar with hardware. H Sort coupling hubs are supplied with an inside sleeve. For technical assistance, please get hold of Lovejoy Engineering.

sleeves, a single cushion set and a single collar with hardware. H Sort coupling hubs are supplied with an inside sleeve. For technical assistance, please get hold of Lovejoy Engineering.

Features

Better torque and bore capability than the C-Line series jaw coupling

Elastomeric cushions are radially removable

Cushions obtainable in SXB rubber and Hytrel

RRC Style Radially Removable Spacer Coupling

RRC Style couplings range from sizes RRC226to RRC2955.

The RRC Style coupling consists of:

two RRC Hub Adapters (consists of bolts)

one Spacer assembly consisting of:

two RRC Jaw rings

1 collar with hardware

1 set of SXB (NBR) cushions

L Sort Coupling

Sizes variety from L035 to L276

Ordering involves choosing UPC numbers for two typical L hubs and a single normal open or solid center elastomer (spider)

SW Variety Coupling

Sizes array from L090 to L190

Ordering demands selecting UPC numbers for two conventional L hubs and 1 snap wrap spider with snap ring

Each L and SW Style couplings, choose hubs from your conventional bore and keyway chart (pages JW-11 and JW-12) maximum RPM for SW + Ring is 1,750 RPM

LC coupling makes use of a snap wrap spider using a collar instead of the retaining ring

Jaw In-Shear Coupling

Ordering requires selecting item numbers for two common hubs, 1 In-Shear elastomer and a single In-Shear ring.

admin

February 20, 2021

C Variety Couplings

The C Kind coupling includes two common hubs, a single cushion set and collar with hardware.

Capabilities

Greater torque and bore capacity compared to the L-Line series jaw coupling

Elastomeric cushions are radially removable

Cushions offered in SXB rubber and Hytrel

RRS and RRSC Form Radially Removable Spacer Couplings

RRS Kind couplings range from sizes RRS090 to RRS225. The RRS Variety

coupling includes:

RRS090 – RRS110:

2 Normal RRS Hubs

one Spacer Assembly consisting of:

two snap wrap spiders w/o ring

two collars with screws

1 spacer

RRS150 – RRS225:

1 Regular RRS Hub

1 Normal RRSC Hub – Drilled for collar

1 Spacer Assembly consisting of:

2 snap wrap spiders w/o ring

2 collars with screws

one spacer

Note:

RRS Kind Inch Hubs provided normal with two set screws at 90°.

Attributes

Regular API based spacers  offered

offered

Radially removable inserts

Regular Lovejoy hub layout with more set screw at 90°

admin

February 20, 2021

The LC Type coupling consists of one particular standard L Kind hub (with out collar attachment), one particular LC Kind hub (delivers collar attachment), a single regular snap wrap center and 1 collar with screws. Characteristics

Radially removable insert

Collar allows for highest speed of three,600 RPM

Collar produced from 1018 Steel

Notes:

These “LC” hubs are drilled and tapped to accept collar mounting screws but the collar and hardware are usually not included.

See L Type (inch or metric) coupling chart for normal hub.

Tolerances for bore and keyways are found in Engineering Information section .

All hubs are supplied common with 1 set screw.

When referencing the amount on this table, consist of 685144 as being a prefix for the amount shown.

AL and SS Style Couplings

The AL Variety coupling includes two hubs and one spider.

Functions

Interchangeable with all hub sizes typical for that L-Line and AL-Line merchandise

Accessible in a variety of different finished bore and keyway combinations

Completed bores passivated for additional rust protection

AL Variety Couplings

The AL Type coupling consists of two hubs and 1 spider.

Attributes

Aluminum material is corrosion resistant

Lightweight

Hubs compatible with common Lovejoy hub design (except AL150)

admin

February 19, 2021

Jaw Sort Coupling Choice Process

The variety procedure for determining the correct jaw coupling dimension and elastomer demands utilizing the charts shown to the following pages. You will find 3 parts to be picked, two hubs and one elastomer. Once the shaft size on the driver and driven from the application are from the same diameter, the hubs chosen will likely be the exact same. When shaft diameters differ, hubs picked will vary accordingly.

Facts necessary before a coupling could be picked:

HP (or KW) and RPM or Torque  of driver

of driver

Shaft sizes of driver and driven products and corresponding keyways

Application description

Environmental disorders (i.e. extreme temperature, corrosive conditions, area limitations)

Ways In Choosing A Jaw Coupling

Phase 1: Identify the Nominal Torque of the application by utilizing the next formula:

Nominal Torque = in-lb = (HP x 63025)/RPM

Nm = (KW x 9550)/RPM

Stage two: Employing the Application Service Elements Chart 1 decide on the service factor which greatest corresponds for your application.

Stage 3: Determine the Design Torque of your application by multiplying the Nominal Torque calculated in Phase 1 from the Application Support Aspect determined in Phase two.

Style Torque = Nominal Torque x Application Services Aspect

Step four: Using the Spider Performance Information Chart 2, select the elastomer materials which very best corresponds to your application.

Phase 5: Employing the Jaw Nominal Rated Torque Chart 3 , find the acceptable elastomer material column to the elastomer selected in Phase four.

Scan down this column to the very first entry the place the Torque Value during the appropriate column is higher than or equal towards the Style and design Torque calculated in Phase three.

Once this value is located, refer to the corresponding coupling dimension during the to start with column with the Jaw Nominal Rated Torque Chart three .

Refer towards the optimum RPM worth for this elastomer torque capability to make sure that the application needs are met. If your necessity is not really pleased at this point, yet another sort of coupling may be expected to the application. Please consult Lovejoy engineering for support.

Phase 6: Review the application driver/driven shaft sizes on the greatest bore size obtainable over the coupling selected. If coupling bore size is not really big ample for your shaft diameter, pick the next biggest coupling that should accommodate the driver/driven shaft diameters.

Phase 7: Working with the UPC number assortment table , find the suitable Bore and Keyway sizes required and locate the amount.

admin

February 19, 2021

Elastomers In Compression

We features 4 sorts of elastomer models to allow for further versatility in addressing distinct application prerequisites. 1 piece styles are utilized in the “L” and “AL” versions (known as spiders)  and many aspect “load cushions” are used in the “C” and “H” model couplings. The load cushions are in sets of six to 14 pieces according to coupling dimension.

and many aspect “load cushions” are used in the “C” and “H” model couplings. The load cushions are in sets of six to 14 pieces according to coupling dimension.

Sound Center Spider

The sound center layout is generally utilized design and style when shafts of the driver and driven gear may be stored separate by a common gap

Open Center Spider

The open center layout makes it possible for for the shafts from the driver and driven to be positioned inside of a brief distance

Open center spiders offer you shaft positioning versatility but possess a reduced RPM capability

Cushions

Applied exclusively to the C and H Kind couplings

Load cushions are held in place radially by a steel collar that’s connected to one of the hubs

Snap Wrap Versatile Spider

Design makes it possible for for easy removal of your spider without having moving the hubs

Lets for near shaft separation the many way as much as the hubs maximum bore

Highest RPM is one,750 RPM with the retaining ring, but when utilized with all the LC Form (with collar) the ordinary RPM rating of your coupling applies

Style is accessible in NBR and Urethane only, and in restricted sizes

Spider Materials

SOX (NBR) Rubber

The standard materials that may be extremely flexible material that is definitely oil resistant

Resembles pure rubber in resilience and elasticity, and operates proficiently in temperature ranges of -40° to 212° F (-40° to 100° C)

Urethane

Has one.five occasions higher torque capability than NBR

Good resistance to oil and chemical substances

Materials presents significantly less dampening result and operates at a temperature array of -30° to 160° F

Hytrel

Flexible elastomer made for high torque and high temperature operations

Operates in temperatures of -60° to 250° F (-51° to 121° C)

Bronze

Rigid, porous, oil-impregnated metal insert solely for lower speed (max 250 RPM) applications requiring substantial torque abilities

Not impacted by water, oil, dirt, or excessive temperatures – operates in temperatures of -40° to 450° F (-40° to 232° C)

admin

February 19, 2021

The Jaw Type couplings are offered in the industry?¡¥s largest selection of stock bore/keyway combinations. These couplings demand no lubrication and deliver very reputable services for light, medium, and hefty duty electrical motor and internal combustion power transmission applications.

Options

Fail-safe ¡§C will nonetheless execute if elastomer fails

No metal to metal make contact with

Resistant to oil, dirt, sand, moisture and grease

Extra than 850,000 combinations of bore sizes

Most styles obtainable from stock in 24 hrs

Applications involve power transmission to industrial equipment which include pumps, gear boxes, compressors, blowers, mixers, and conveyors. Jaw Type couplings can be found in 24 sizes from a minimal torque rating of 3.5 in¡§Clbs to a highest torque rating of 170,004 in¡§Clbs and a bore array of .125 inches to 7 inches.Our common bore system covers AGMA, SAE, and DIN bore/keyway and spline bore combinations.

The Jaw Sort coupling is obtainable in a assortment of metal hub and insert supplies. Hubs are made available in sintered metal, aluminum, bronze, steel, stainless steel, and ductile iron.

L Sort

Coupling offers regular shaft-to-shaft connection for common industrial duty applications

Normal L Variety coupling hub products are either sintered iron or cast iron

LC Sort

Utilizes the common L Type hubs which has a snap wrap spider and retaining ring

Suited for applications more than one,750 RPM

AL Type

Aluminum hubs provide light bodyweight with lower overhung load and minimal inertia

Superb resistance to atmospheric conditions, perfect for corrosive environment applications

SS Kind

The SS Style coupling provides maximum protection towards harsh environmental disorders

Sizes SS075-SS150 accessible from stock, other sizes available on request

RRS Type

Center ?¡ãdrop out?¡À part of this coupling gives proper shaft separation, even though also enabling simple elastomer installation without having disturbing the hubs or requiring the realignment of shafts

Accommodates American and European business standard pump/motor shaft separations

The spacer  is produced of glass reinforced plastic, cast iron, or aluminum

is produced of glass reinforced plastic, cast iron, or aluminum

SW Variety

Regular L Kind coupling which has a snap wrap elastomer with retaining ring

Very well suited for normal shaft to shaft connection on the whole industrial function applications below one,750 RPM

C & H Varieties

Couplings deliver regular shaft-to-shaft connection for medium (C) and Heavy (H) duty range applications

Standard C coupling hub is made of cast iron, although the H is constructed of ductile iron